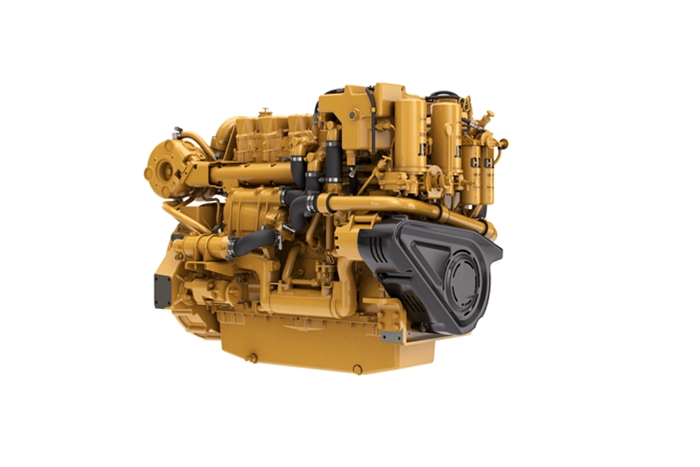

Product Specs

Power Rating

- Power Range

- 404 - 660

- Minimum Rating

- 404 BHP

- Maximum Rating

- 660 BHP

Engine Specifications

- Aspiration

- TA, TTA

- Rotation from Flywheel End

- Counterclockwise

- Bore

- 5.7 in

- Displacement

- 1106 in³

- Configuration

- In-Line 6, 4-Stroke-Cycle Diesel

- Stroke

- 7.2 in

Dimensions & Weights

- Height

- 51.2 in

- Length

- 73 in

- Width

- 44.6 in

- Dry Weight

- 1950 lb

Standard Equipment

-

- Air Inlet System

-

- Separate circuit after-cooled (SCAC)

- Open Crankcase Ventilation (OCV) system

- Turbocharger, jacket water cooled

- Turbocharger inlet, 152 mm (6 in) OD straight connection

-

- Control System

-

- Programmable low idle

- Electronic diagnostics and fault logging

- Electronic fuel/air ratio control

- Engine Protection Mode for extended ambient conditions - EPA Tier 3 Ratings Only

- 70-pin customer connector

- Three types of throttle inputs (primary/ secondary PWM, 0-5V, 4-20mA

-

- Cooling System

-

- Separate Circuit After-Cooling (SCAC) for both HEX and Keel cooled engines

- Engine JW and SCAC Shell & Tube Heat Exchangers for HEX cooled engines

- SCAC pump, gear driven, for HEX cooled engines only

- Jacket water pump, gear driven

- Auxiliary water pump, gear driven

- Sea water pump, bronze impeller, gear driven

- SCAC and JW shunt tanks for maintaining proper pump inlet pressures

-

- Exhaust System

-

- 152 mm (6 in) round flanged outlet

- Water-cooled exhaust manifold & turbocharger

-

- Flywheels & Flywheel Housings

-

- Flywheel Housing, SAE No. 0

- Flywheel, 18 inch, 136 teeth

- SAE standard rotation

-

- Fuel System

-

- Front service simplex fuel system

- Fuel transfer pump, gear driven

- Manual fuel priming pump

- Hybrid fuel line design

-

- Lube System

-

- Front service simplex oil system

- Center sump oil pan:

- Front and top service oil filler locations

- Front service dipstick

- Oil pump, gear driven

-

- Mounting System

-

- Front support - adjustable

-

- Power Take-offs

-

- Hydraulic Pump Drive

- Crankshaft Pulleys

- Front Stub Shaft

- Front Enclosed Clutch

-

- General

-

- Front damper guard

- Front service engine

- Common electrical bonding point

- Engine does not ship with zinc components

- NOTE: These engines are for constant speed generator set applications only, and NOT to be used for variable speed applications

Attachments

-

- Exhaust System

-

- Dry Elbows

- Water-Cooled Elbows

- Flexible Fitting

- Flange

- Muffler

- Muffler Spark Arresting

-

- Air Inlet System

-

- Air Inlet Adapter

-

- Charging System

-

- Battery Chargers

- Charging Alternators

- Alternator Mounting Group

- Ammeter

-

- Control System

-

- MECP I - Marine Engine Control Panel

- Caterpillar Alarm and Protection

- Load Sharing Attachment

-

- Cooling System

-

- Aux Expansion Tank Flange Kit

-

- Fuel System

-

- Duplex Fuel Filters

- Fuel Cooler

- Primary Fuel Filters

- Flexible Fuel Lines

-

- Instrumentation

-

- Instrument Panels

- OEM Wiring Harness

- Gauges

- Oil Level Sensor

-

- Lube System

-

- Duplex Oil Filters

- Sump Pump

-

- Power Take-offs

-

- Crankshaft Pulleys

- Front Stub Shaft

- Hydraulic Pump Drive Adapter

- Front Enclosed Clutch

-

- Protection System

-

- Marine Classification Society and SOLAS

-

- Starting System

-

- Electric Starting Motors - Single 24 Volt

- Air Starting Motor

- Air Start Accessories

- Starting Aids - JW Heaters

- Battery Sets - 24 Volt - Dry

-

- Mounting System

-

- Front Support

- REAR ENGINE SUPPORT

-

- Packing

-

- Engine Protective Cover

- Storage Preservation

- Export Packing